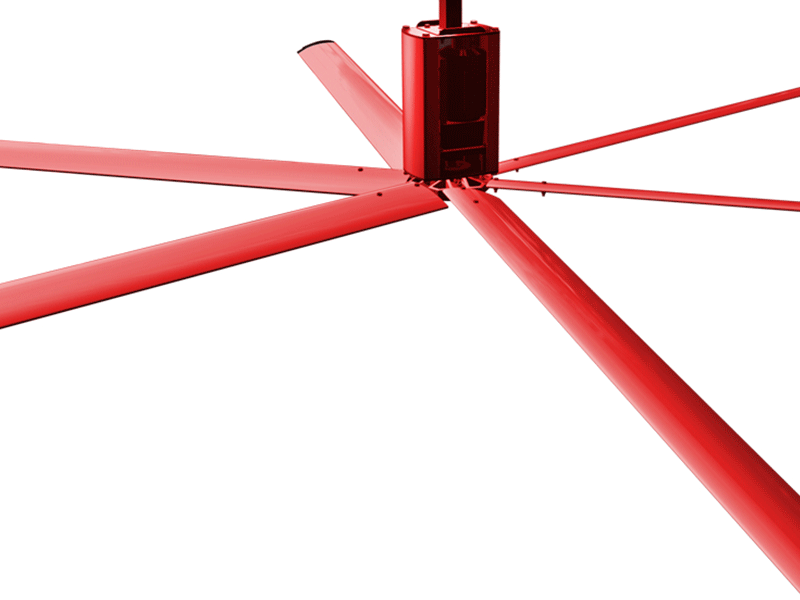

In a warehouse, staying cool in the summer means it gets loud with industrial fans. You exchange uncomfortable temperatures for difficulty in hearing and communication. Heat, and your efforts to…

In a warehouse, staying cool in the summer means it gets loud with industrial fans. You exchange uncomfortable temperatures for difficulty in hearing and communication. Heat, and your efforts to…

How to buy Pallet Rack systems: For a growing company, the next step is to invest in a pallet racking system. However, the process of choosing the right pallet rack…

© 2024 Atlantic Rack. All Rights Reserved. Atlantic Rack & Shelving. | Web Design By Afro.