Warehouse docks serve as a critical access point for any storage facility. Dock equipment refers to all the material handling solutions used to assist with the loading and unloading of materials from trucks to buildings. These products are designed to maximize efficiency and safety in docking areas, improving your warehouse productivity!

At Atlantic Rack we carry a wide range of quality dock equipment to help improve your daily tasks and make your operations more efficient. Most of our docking equipment is usually in-stock and available for fast delivery or pick up.

- Dock Seals & Shelters

- Pit Dock Levelers

- Edge-of-Dock Levelers

- Vehicle Restraints

- Steel Dock Boards

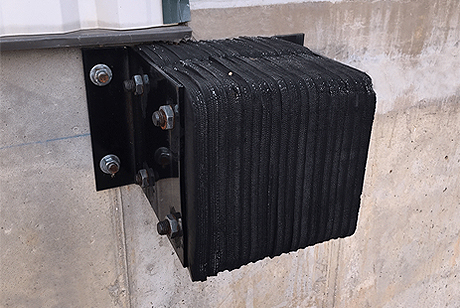

- Laminated Dock Bumpers

- Folding Gates

- Dock Lamps

- High Performance Doors

- Fall Guard Doors

- Bug Screen Doors

.png)