Pallet Shuttle Systems

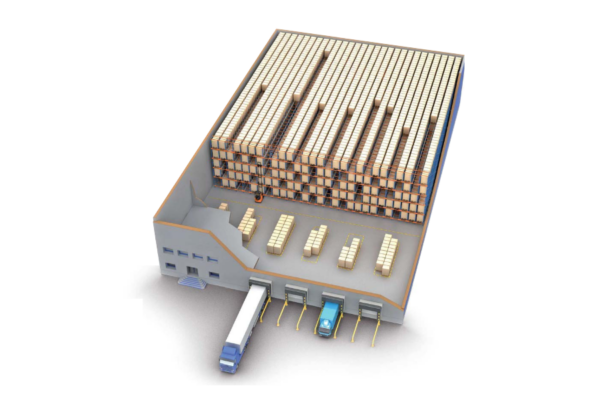

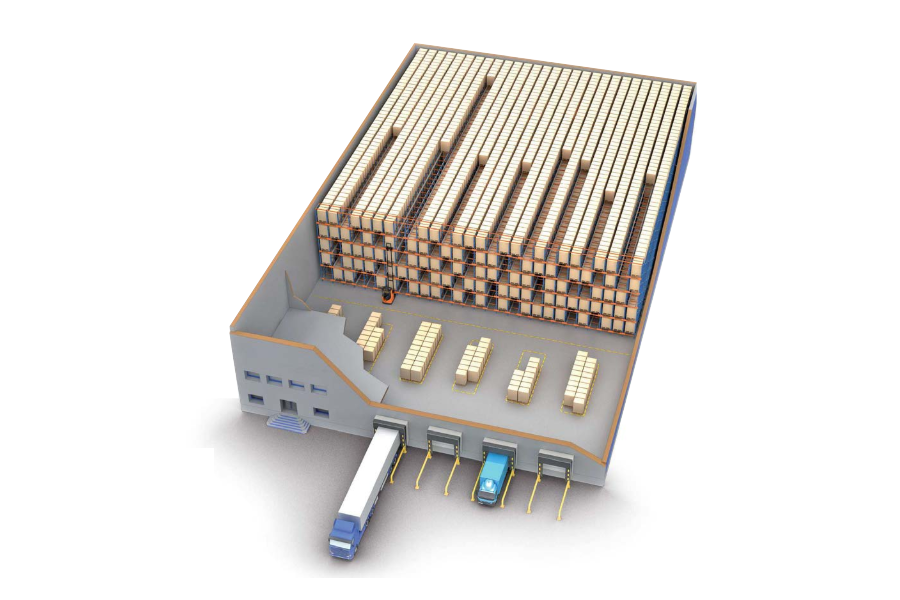

The Pallet Shuttle System represents a leap in warehouse automation, offering a sophisticated solution for managing storage and retrieval operations. This innovative system is an advanced version of Automated Storage and Retrieval Systems (AS/RS), transforming the way businesses approach inventory management.

With the ability to handle deep lane storage for over 110 pallet positions, the Pallet Shuttle System ensures efficient space utilization by adopting both FIFO (First In, First Out) and LIFO (Last In, First Out) strategies.

Optimized for varying industrial environments, from chilled storage to dry warehouses, the Pallet Shuttle System is the epitome of high-density and streamlined inventory management.

Advantages of Pallet Shuttle System:

- Maximized Storage Utilization: Utilizes deep lane storage to optimize space.

- Enhanced Operational Efficiency: Robotic shuttles reduce the need for forklifts, streamlining warehouse operations.

- Scalable Productivity: Adaptable to varying pallet sizes and types, accommodating the diverse needs of businesses.

- Robust Inventory Management: Seamless integration with warehouse management systems for real-time tracking.

- Improved Safety: Minimizes the risk of accidents by eliminating the need for forklift entry into storage lanes.

- Cost-Effectiveness: Lowers operational expenses through efficient handling and reduced labor costs.

- Versatility: Suitable for a wide range of industries, including manufacturing, e-commerce, and food and beverage sectors.

- Durability: Engineered to perform in extreme temperatures, ensuring reliability and longevity.

HUGE STOCK & READY TO SHIP!

Our huge selection of pallet racks is in-stock and ready to ship globally!

Ready To Enhance Warehouse Storage Space? View Catalog

Types of Pallet Shuttle Systems

Pallet Shuttle Systems offer unparalleled flexibility with configurations designed for specific warehouse needs. Available in two primary models, each system is engineered to maximize space and efficiency within your storage facility.

Semi-Automated: The semi-automated model incorporates motorized shuttles that carry pallets into deep storage lanes. This system is ideal for operations where high-density storage and increased productivity are essential.

High-Speed Automated: For operations demanding the ultimate in efficiency and throughput, the high-speed automated system features advanced robotics, executing rapid storage and retrieval tasks with precision.

Components of the Pallet Shuttle System

Our Pallet Shuttle System integrates state-of-the-art components that work cohesively to deliver exceptional performance.

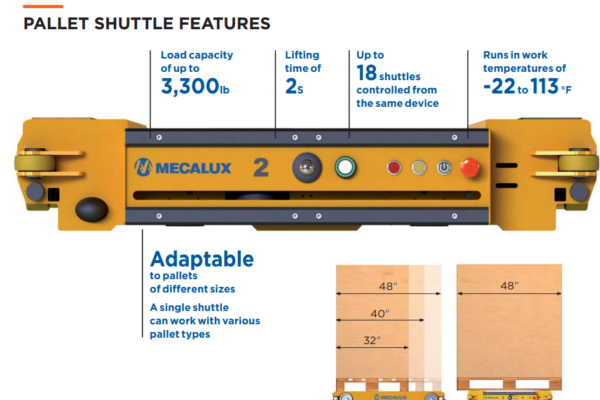

- Robust Shuttle Units: Each unit can transport up to 3,300lb, handling different pallet sizes and withstanding extreme temperatures.

- Intelligent Management Software: Compatible with Easy WMS for error-free, real-time inventory control.

- Safety Enhancements: Includes locking systems and optional bilateral safety scanners to ensure safe operation.

Features of the Pallet Shuttle System

The Pallet Shuttle System comes with an array of features that streamline warehouse operations, improve safety, and enhance storage capacities.

- Wi-Fi Controlled Operations: Seamless management of shuttles through an intuitive tablet interface.

- Versatile Shuttle Movement: Capable of high-speed navigation at 295’/min when unloaded, ensuring swift handling.

- Advanced Battery Technology: Equipped with lithium batteries for extended operation, up to 10 hours at full capacity.

- Sophisticated Sensing Capabilities: Integrated sensors adept at identifying and managing different pallet types.

.png)