Pet Supermarket

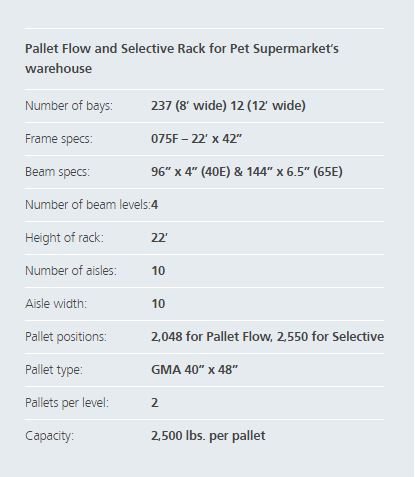

Pet Supermarket is one of the largest small format specialty retailers of pet food and pet-related supplies based in the southeastern U.S. The company operates 182 stores offering customers a broad assortment of premium and holistic pet food and supplies. In order to expand its distribution network, the retailer recently leased 97,000 ft² at the Bridge Point Davie distribution facility in Davie, Florida, and decided to equip the space with a mix of Interlake Mecalux Pallet Flow and Selective racking.

.png)

Proposed solution

Proposed solution