Gloval Shipping is an International Freight Forwarding company with more than 20 years of experience moving freight between the US and Latin America. With offices in Miami, Guayaquil, Lima and Panama City, they are committed to offer effective logistics services to customers within these locations.

Since Miami is the world’s largest gateway to Latin America, it serves as the headquarters for Gloval Shipping. This warehouse leverages the most massive number of freight forwarding services of the company. Miami offers a strategic location that allows Gloval to offer their services effectively to their Latin American customers.

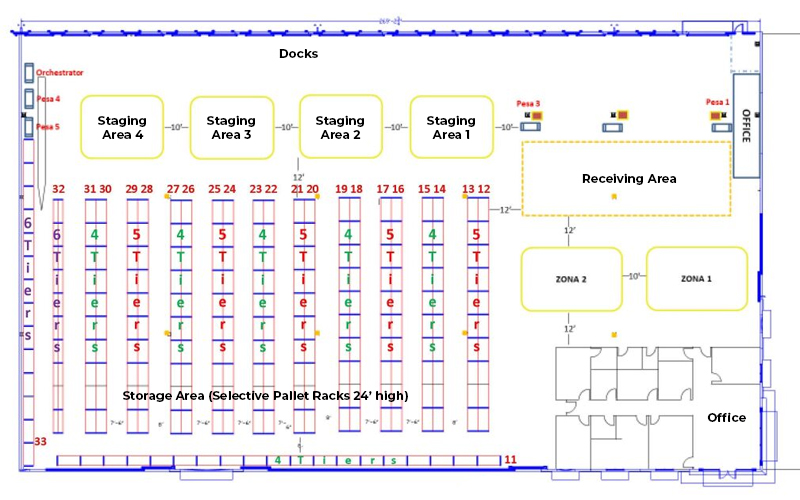

.png)