Don’t let summer affect your business operations.

There is nothing worse than a warehouse in the summer. The air is hot, stuffy and stagnant. Warehouse personnel feel every degree in their attempt to keep product moving on and off the shelves, load and unload trucks and conduct inventories. This slows them down and increases the possibility of mistakes due to discomfort and distraction. By increasing air circulation, you can increase efficiency, accuracy and save money in the process.

Many facility managers believe changes in the HVAC (heating, ventilation, and air conditioning) system that controls heating and cooling are the way to regulate temperature in the warehouse environment. The main issue, however, is air movement Fresh air is cooler air and a constant rotation of fresh and old air is the key to regulating not just temperature but the atmosphere of the warehouse in general.

While there are HVAC (heating, ventilation, and air conditioning) solutions, they are costly to install, maintain and run every month. HVAC (heating, ventilation, and air conditioning) solutions press air through layers to achieve desired temperatures. High speed fans blow air through the layers, essentially just moving hot air but doing nothing to cool it.

Let us help you increase your warehouse productivity Learn More

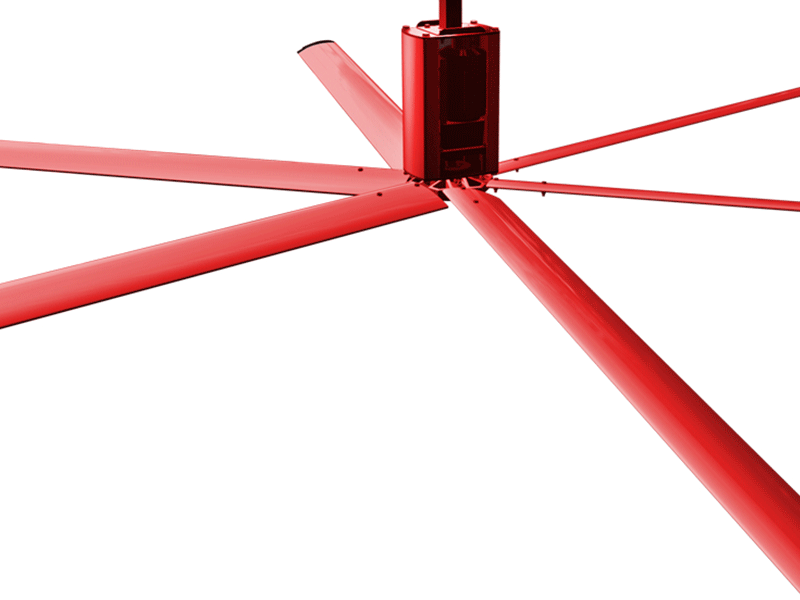

There is a solution that combines both methods, through the installation of MacroAir High Volume, Low Speed (HVLS) industrial fans, stand-alone or in conjunction with an HVAC system. MacroAir HVLS industrial fans de-stratify the air. That is, they prevent the heat layers from building up, funneling cool air throughout the entirety of the facility. It effectively both cools and moves the air at the same time.

This improves productivity through out the used of industrial fans by resulting in:

- A happy workforce. A comfortable work environment is critical to good morale and an industrious work force. Employees will not complain of being hot or cold, will not have to wear extra layers or coolant wraps around their necks and can focus on the task at hand. It also improves the quality of the air in the building, making it more pleasant to work in.

- Lower energy costs. HVLS industrial fans can improve air circulation in other than non-climate controlled facilities. They can also reduce the operating heating and cooling costs in conditioned facilities as well.

- Quick return on investment. Facility owners have saved up to 30% on heating and cooling costs by using MacroAir indusrtrial HVLS fans. This is because the air is constantly moving at all levels, keeping temperatures comfortable while giving management the ability to raise thermostat set points before the HVAC system would kick in to maintain them.

- Reducing rework. Rework due to error costs employers hundreds of thousands of dollars per year. Increased comfort levels make it easier for employees to concentrate and do the job right the first time. Beyond employees, regulated temperatures are better for product and storage. Condensation can damage pallets, for instance, and cause employees to be pulled away from value added work to restack pallets and reshelve product.

- Safety. The effects of condensation can also lead to slick floors, increasing the possibility of falls or slips. According to a Top 10 list published by Liberty Mutual, falls on the same level (#2), falls to a lower level (#4) and slips and trips without falls (#7) accounted for 27.6% or $16.5 billion dollars in direct costs of workplace injuries in 2012.

Equip your warehouse for this summer extreme heat. $200 off MacroAir Fans. I want this

Using MacroAir HVLS industrial fans gives businesses a unique opportunity to maintain a high productivity level with happy and healthy employees and raise profit potential while reducing risk and employee turnover, making them a win-win for every person in the organization.

.png)